How to avoid shutdowns and downtime in critical infrastructure

Critical infrastructure is evolving. Scaling with a growing population and fast-moving economy, digital technologies are essential to ensure Australia’s defence, national security, and economic and social stability.

In today’s landscape, even a minor shutdown or a few minutes of downtime can be detrimental to industries being relied upon to deliver many of the essentials of daily modern life. So, how do we avoid shutdowns and downtime in critical infrastructure during a period of digital transition?

In this blog, we’ll explore four primary causes of downtime and how to solve them through industrial digitalisation solutions.

Before we start! What industries are considered critical infrastructure?

The 11 critical infrastructure sectors outlined by the Australian Government in the Security of Critical Infrastructure (SOCI) Act are outlined in the graphic below.

.png?width=800&height=500&name=Critical%20infrastructure%20list%20(1).png)

1. Asset failure

Downtime cause: Asset failure

Solution: Automation

Result: Data collection, Asset monitoring

Digital transformation starts with integrating SCADA, PLCs, and RTUs to automate repetitive manual tasks, and digitally connect your equipment and machines for enhanced monitoring.

But first, what is SCADA, and what are PLCs and RTUs?!

SCADA – Supervisory Control and Data Acquisition – is a system of software and hardware elements that can both control, monitor, and gather information from machines and processes.

PLC – Programmable Logic Controller – is a part of the SCADA architecture that communicates and translates data it gathers from any asset typically found in a manufacturing environment such as sensors, motors, pumps, valves, and more. Feeding this back into the SCADA system via microcomputers, PLCs enable in-depth data analysis by the user. Ideal for manufacturing environments in factories or plants, PLCs are also utilised in water treatment plants and some large energy generation plants.

RTU – Remote Terminal Unit – is another piece of hardware for data acquisition and control that can integrate within the SCADA architecture. RTUs are a must-have in modern energy infrastructure to enable control and data insights from key assets such as substations, power generation or networks. Also utilised in the water sector across remote pump stations and assets, and in the transport sector across Intelligent Transport Systems (ITS), RTUs enable smart management of critical infrastructure environments.

In critical infrastructure, where asset failure can cause a catastrophic impact on businesses, communities, and society at large; digital transformation is a must – but also not a silver bullet to solve downtime and shutdowns.

Digitally connecting critical assets allows you to begin collecting data about every aspect of your operation. The next step? Turning that data into actionable insights to support data-driven decision-making.

Learn more about the digital technologies supporting smarter asset maintenance and its impact on downtime in this blog.

2. Inadequate maintenance

Downtime cause: Inadequate maintenance

Solution: Integrated data analytics

Result: Asset management, Predictive maintenance

Even with our critical infrastructure assets digitally connected (see step 1), we need a way to monitor our assets effectively using the raw data that digitisation enables.

Knowing when to maintain or repair equipment can be challenging in critical infrastructure industries, where, historically, equipment assessments occur on-site by a technician or electrical engineer.

Often issues arise in between site visits or are accidentally missed during assessment, causing unplanned downtime or, in worst-case scenarios, even shutdowns. The integration of digital tools as a layer above your SCADA and PLC unlocks your ability to delve deep into analytics to make smarter, data-driven decisions.

Drawing insights from raw numbers can be challenging, even for those with an engineering background – especially with the massive amount of data involved in running critical infrastructure operations 24/7, 365 days a year.

An integrated analytics solution is the answer!

Software solutions like Seeq, AWS, AVEVA, OFS, and TilliT, provide purpose-built digital tools suitable for a wide range of industries, with specific functions that enable real-time asset management, enhanced visibility, and control.

Predictive maintenance is the beauty of integrated data analytics. With pattern recognition, machine learning, and artificial intelligence (AI), you can harness advanced technology to be alerted when an asset within your critical infrastructure operation requires maintenance – ahead of time.

For more information about the best way to get the most out of your data, read about the 6 steps to a successful digital transformation.

3. Cyber threat or breach

Downtime cause: Cyber threat or breach

Solution: SOCI Act review (cyber security assessment)

Result: Increased cyber resilience

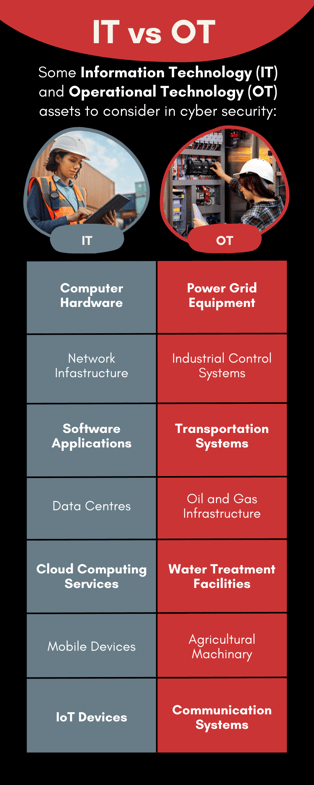

Cyber security threats are a major cause of downtime. Typically, when cyber is mentioned, we automatically think about information technology (IT), but operational technology (OT) is just as important in critical infrastructure.

Remote access to industrial control systems (ICS) and IT-OT infrastructure assets, which became a widely adopted practice during the COVID-19 pandemic, has increased the vulnerability of these systems.

The Australian Government has been proactive in developing robust cyber security frameworks to ensure the safety of Australia’s critical infrastructure, and adhering to these guidelines is a requirement for most critical infrastructure operations.

The Security of Critical Infrastructure (SOCI) Act, introduced in 2018, was introduced to improve the cyber security protection and resilience of the Critical National Infrastructure (CNI) industry sector.

In a constantly evolving digital landscape, there is no perfect gold standard solution available in cyber security, but complying with the SOCI Act through a professional review process can support understanding your requirements and developing resilience.

In the meantime, check out these three tips to achieve cyber security compliance.

4. Human error

Downtime cause: Human error

Solution: Upskilling, talent

Result: Improved efficiency

No one is perfect – people make mistakes! Unfortunately, in critical infrastructure, we cannot afford to let human errors be the cause of downtime or shutdowns – and we certainly need to minimise the risk where possible.

With digitisation becoming more common across all critical infrastructure industries, the need for digital skills is imperative. Upskilling existing workers is a step that is often missed as part of a digital transformation strategy when it should be a priority.

Remaining transparent with employees while implementing new technologies is key. Explain clearly how their role may change and provide them with the necessary training to prepare them to adapt and thrive in a technology-driven environment.

Registered training organisations such as Skills Lab offer industry-bred training courses in industrial automation and control, instrumentation, big data and cloud-based systems to help current and future industry workers stay ahead of the rapidly changing industry.

If the roles you need to be filled are in highly specialised areas or are in regional or difficult environments that are hard to fill – specialist consultancy services are available that match high calibre technical expertise with these unique roles.

Learn more about the top skills to thrive in Industry 4.0, according to Skills Lab Training and Operations Manager, Dr Gary Allwood.

Ready to start driving change? Take the Digital Diagnostic.

This blog outlined four key factors that lead to downtime and shutdowns in the critical infrastructure sector. Whether you are just starting your digital transformation journey to address these challenges, or already well on your way – the need for change is clear.

Constantly changing technology, limited resources, short-term expectations of return, and the complicated ‘people’ factor can be barriers to driving change – but organisations need to move today to create tomorrow.

Now, more than ever, it is important to ask – ‘Where is your organisation on its digital transformation journey compared to where you could be?’

To answer this all-important question, SAGE has developed The Digital Diagnostic!

One comprehensive diagnostic tool can help your organisation:

- Gauge where you are in your digitalisation phase and identify what to do next.

- Discover strengths and find out what elements are missing to maintain your competitive edge and become better connected.

Keep Australia’s critical infrastructure secure. Take the Diagnostic today.

.webp?width=457&height=173&name=Sage-Group-Embedded-Expertise-Logo(1).webp)